Case overview

In the dynamic world of automotive engineering, the selection of materials proportion for brake systems stands as a cornerstone of innovation.

Typical KPIs calculation involve testing methods that irreversibly alter or damage the brake: this precludes its continued use or analysis. The importance of optimizing the number of destructive measurements lies in balancing the need for accurate data with the constraints imposed by resource availability, cost, and time.

Mixture designs determines the optimal combination of ingredients or components to achieve desired properties or outcomes while minimizing costs or meeting constraints.

This project seeked to uncover the ideal ingredients that elevate braking performance to new heights.

Mixture Design

Mixture design, also known as mixture experiments or mixture modeling, is a statistical method used to optimize the composition of mixtures or blends consisting of multiple ingredients or components. This approach is commonly employed in various fields such as chemistry, materials science, pharmaceuticals, food science, and industrial engineering.

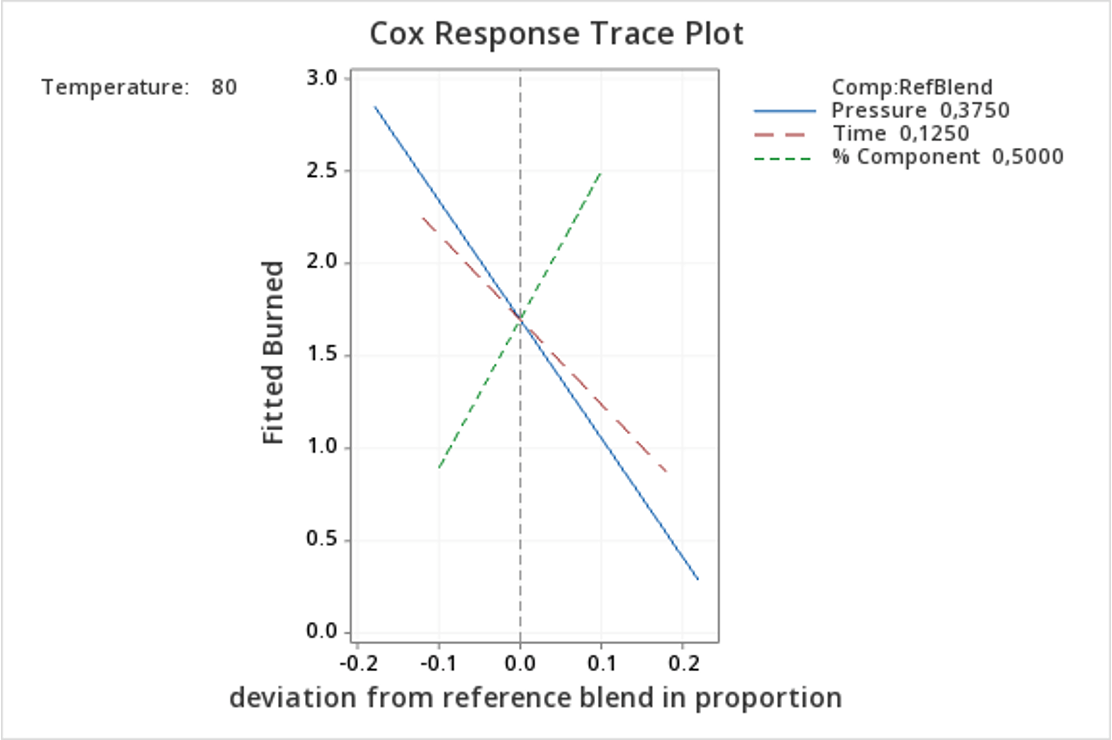

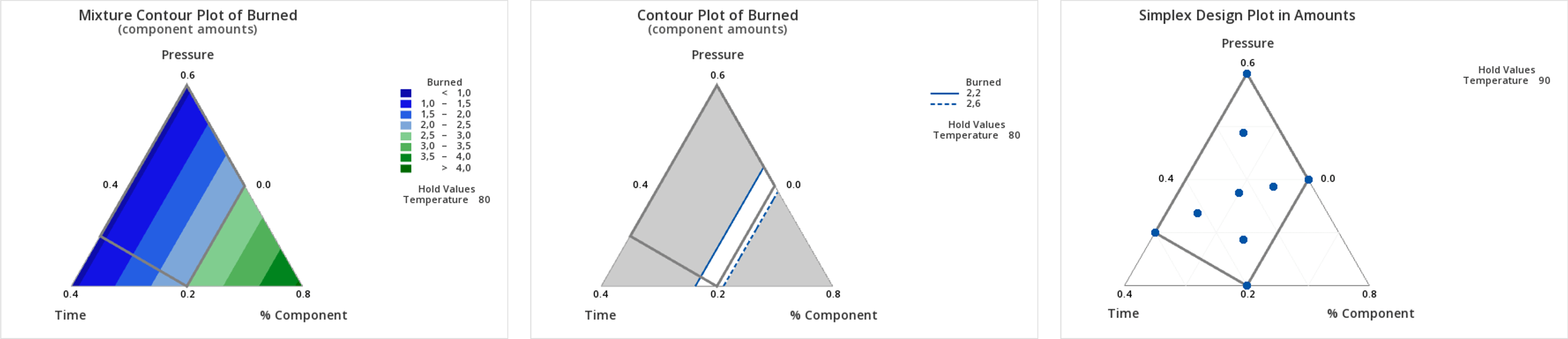

Results

The project aimed to identify the optimal ingredients for high-performance brake systems through an “Extreme Vertices” mixture design.

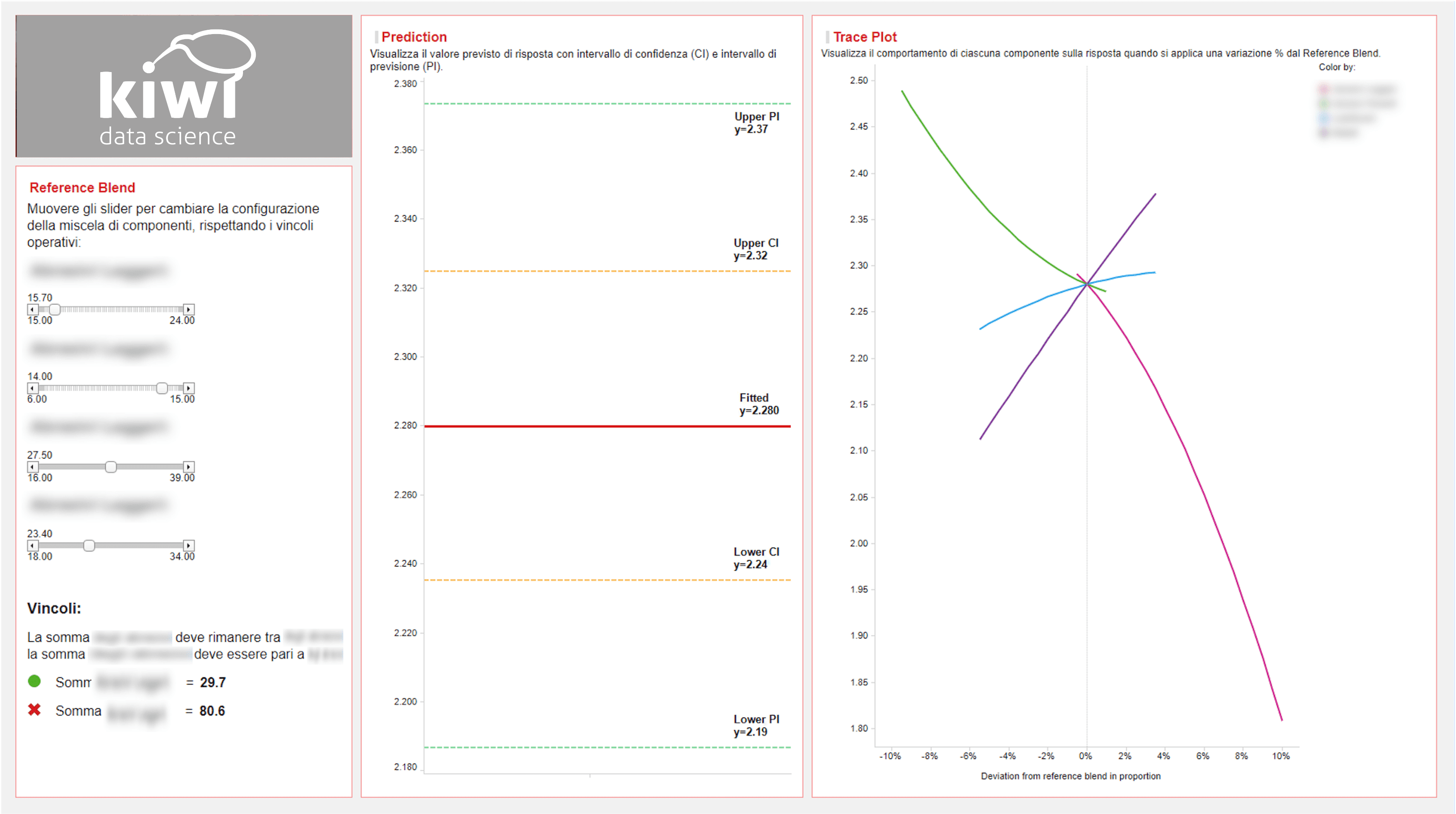

The experimental data collected from the project serves as the foundation for developing an interactive dashboard aimed at simulating the performance of new configurations using a Monte Carlo approach.