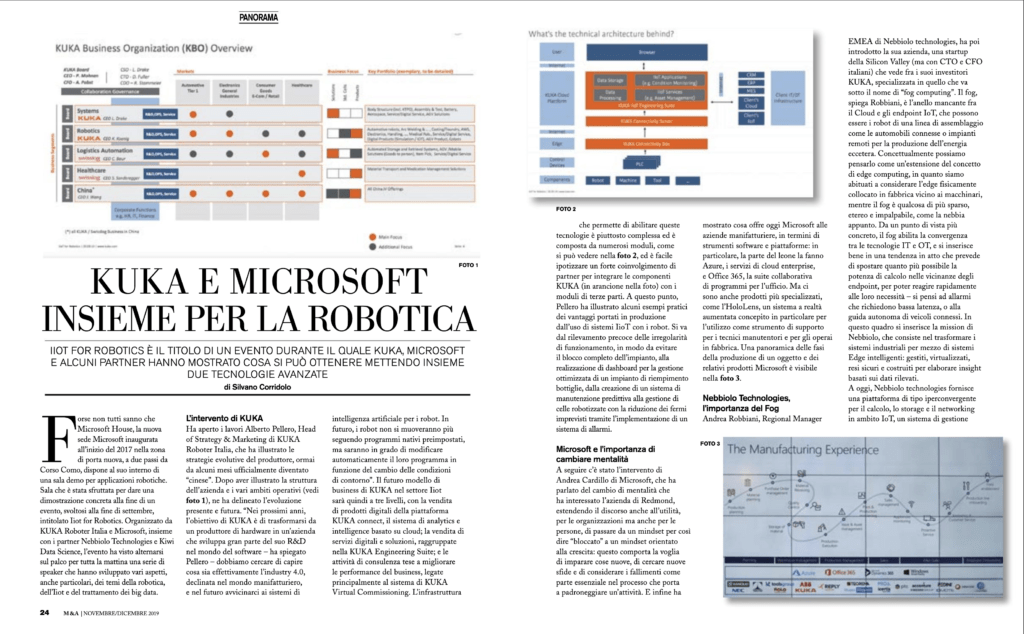

Empowering Manufacturing through Data Science

Our manufacturing services are dedicated to transforming the manufacturing sector through advanced analytics, machine learning, and data-driven insights.

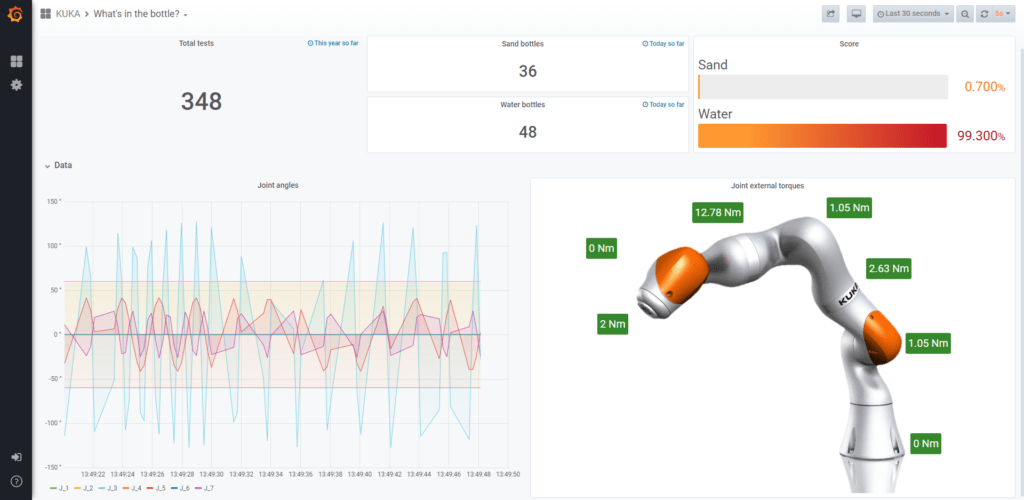

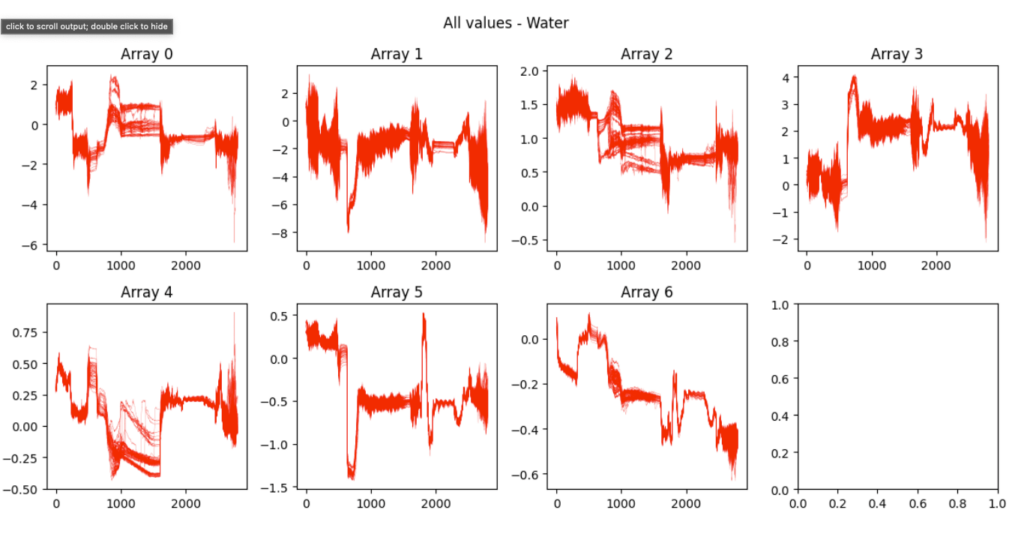

By harnessing advanced analytics and artificial intelligence, manufacturers gain insights from vast datasets, enabling informed decision-making, predictive maintenance, and streamlined operations. Adaptive production systems, driven by data science, align with market demands, minimizing inventory and enhancing responsiveness. Moreover, data science enhances quality control, ensuring adherence to standards and fostering continuous improvement. In the Industry 4.0 landscape, data science isn’t just a choice; it’s a necessity for manufacturers navigating the complexities of a competitive global market.