Because Data Speak

Louder Than Words

Unleashing Artificial Intelligence for empowering decisions: elevate your data with Kiwi’s advanced analytics consulting and solutions

Experience the power of data science

Tailored Consultations and Solutions Spanning Across Diverse Sectors. Discover How Our Customized Approaches Can Elevate Your Business, Regardless of the Industry You’re In.

Services & Solutions

We provide a full range of modern digital services.

Production Monitoring

Datalake Design

Automatic Reporting

Failure Prediction

Clustering & Segmentation

Real Time Alerting

Industrial Statistical Training

Yield/Cost Prediction

Our Products

Understanding the intricacies of your data is paramount to unlocking your business’s full potential. Transform raw data into informative reports and dynamic dashboards. Scarlet is a suite of tools that allow data exploration, business process monitoring, anomalies detection and production performance forecasting.

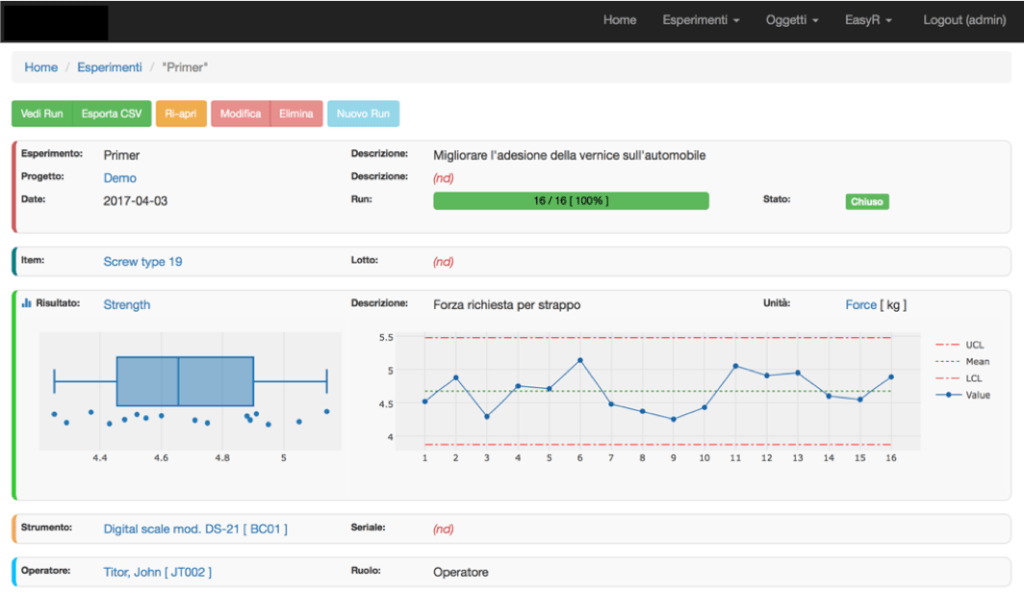

Nabu

Nabu is cloud-based / on-premise software fully dedicated to R&D data collection and with several tools for the Statistical Quality Analysis (SQA). It works within the data lake layer and offers a web user interface that is connected to a powerful relational database. Nabu is designed to help Minitab users to collect and prepare data.

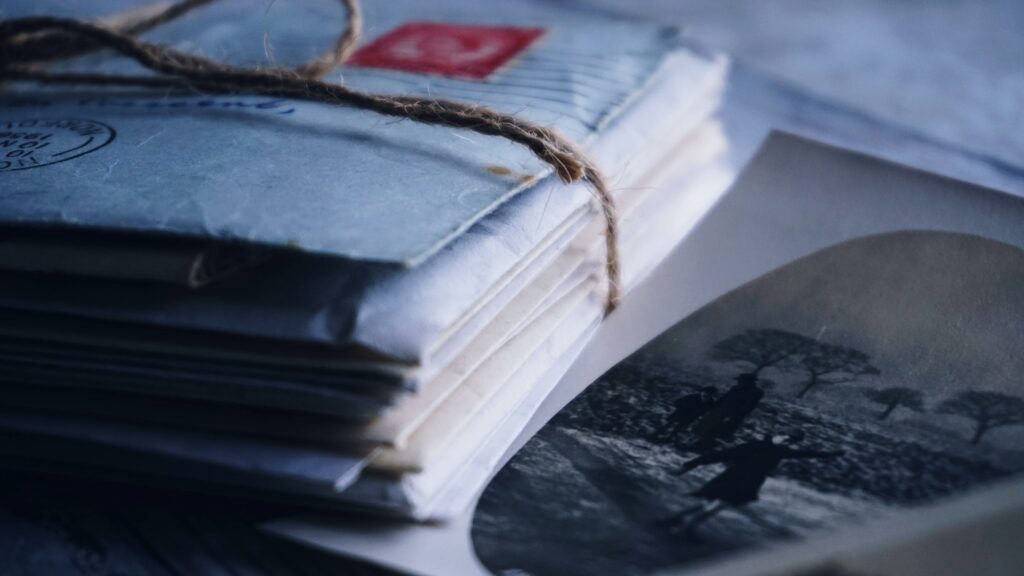

Maily

Maily is a cloud-based/on-premise software designed for the world of high-volume printing and mailing, ensuring compliance with postal regulations and minimizing shipping costs.